Revolving Excellence: The Impact of Trommel Screens in Product Sorting

Maximize Recycling Outcome With Trommel Screens: a Comprehensive Guide

As we aim to maximize the reusing outcome, one device that has gained substantial focus is the trommel display. We will certainly explore the factors that must be thought about when picking a trommel screen and dig into methods that can be used to optimize reusing result.

The Value of Trommel Screens

Trommel displays play an essential function in different sectors as a result of their ability to efficiently separate and classify different products. These equipments are designed to sift and turn with a range of materials, such as dirt, crushed rock, garden compost, and sand, efficiently separating them based on dimension and thickness. This ability to different materials is of utmost value in sectors such as mining, building, waste monitoring, and recycling.

Among the essential reasons trommel displays are so important is their payment to waste decrease and recycling initiatives. By properly dividing products, these displays enable the recovery and reuse of beneficial resources from waste streams. In reusing centers, trommel screens are typically used to arrange various types of recyclable products, such as plastics, metals, and paper, making certain that each material is properly classified and processed for additional use.

In addition, trommel screens also play a vital duty in the mining sector. trommel screen. They are used to divide beneficial minerals from waste materials, boosting overall effectiveness and minimizing the ecological impact of mining operations. By separating the products based on dimension and density, trommel displays aid to make best use of the removal of useful minerals while lessening the quantity of waste that needs to be disposed of

How Trommel Screens Work

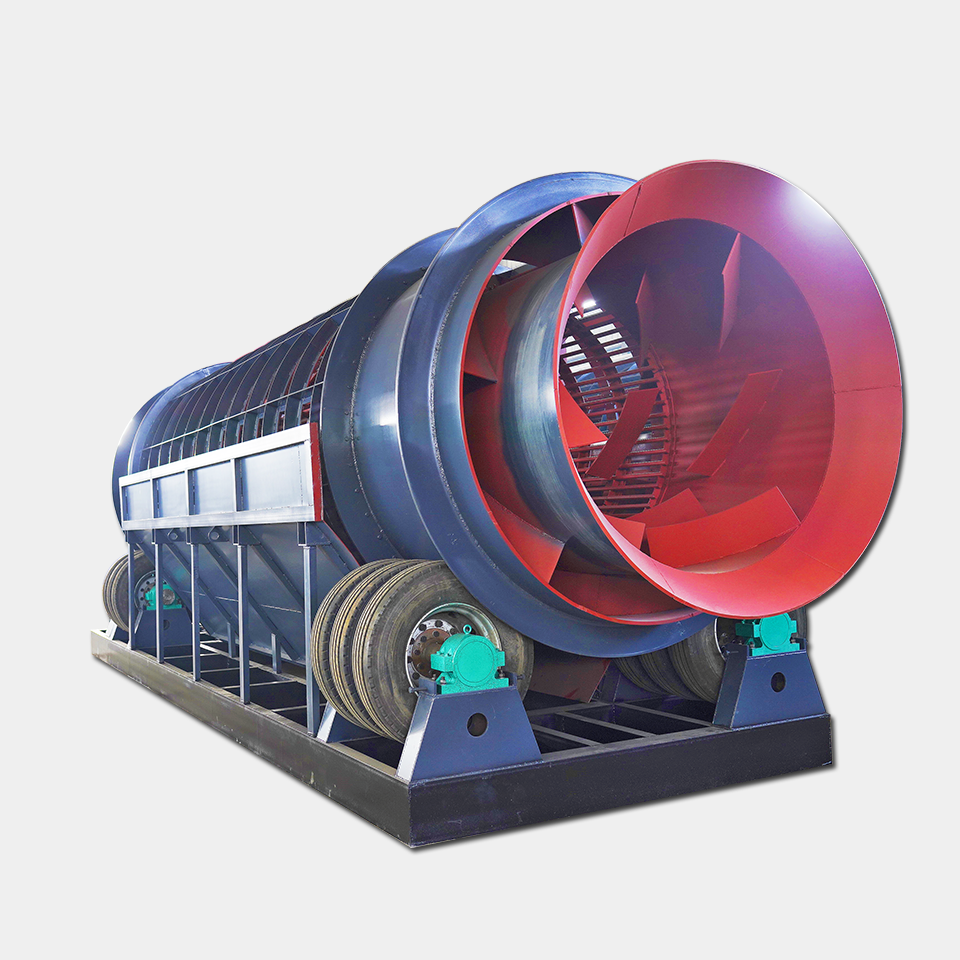

Trommel screens run by turning and sifting with numerous materials to effectively different and categorize them based on dimension and thickness. These screens include a cylindrical drum that is tilted on its axis. The drum is normally made from mesh or perforated plates, permitting the product to pass through while keeping larger fragments.

As the drum turns, the product is fed into the top end. The larger bits are maintained inside the drum, while the smaller bits pass via the mesh or openings. The rotation of the drum helps to raise and tumble the material, helping in the splitting up procedure.

The speed of rotation and the disposition of the drum can be adjusted to manage the sieving procedure. By changing these criteria, operators can enhance the separation of various products (trommel screen). As an example, larger materials will work out at the end of the drum because of gravity, while lighter materials will be carried to the leading and discharged.

Trommel screens are typically made use of in reusing facilities, construction websites, and mining procedures. They can successfully refine a wide variety of materials, such as compost, wood chips, gravel, and minerals. The capacity to categorize products based on size and density makes trommel screens a vital device for optimizing recycling outcome.

Secret Advantages of Using Trommel Screens

One of the considerable benefits of utilizing trommel screens is their capacity to effectively separate and categorize a large range of materials based upon dimension and thickness. This capacity is essential in numerous sectors, including recycling, waste, and mining administration. Trommel screens are designed with turning round drums that have perforated plates or displays. As the material goes into the drum, it is raised and toppled, enabling the smaller sized bits to pass with the openings while the larger ones proceed to helpful hints move along the drum. This procedure ensures that the desired products are separated and identified precisely.

By efficiently arranging products based on size and density, trommel displays help enhance the top quality and purity of the last item. Trommel screens additionally help lower waste and conserve costs by minimizing the requirement for hands-on sorting and minimizing the amount of product sent out to garbage dumps.

An additional advantage of trommel displays is their flexibility. They can manage a vast array of products, including accumulations, garden compost, local strong waste, and also polluted dirt - trommel screen. This flexibility makes trommel displays a necessary tool for different markets, permitting them to process different types of products easily

Factors to Consider When Selecting a Trommel Display

When choosing a trommel display, it is important to very carefully take into consideration various variables to guarantee optimal efficiency and viability for specific application requirements. One of the very first factors to consider is the dimension and ability of the trommel display. The dimension should be suitable for the quantity of product to be refined, while the ability ought to match the desired result. Furthermore, the design and building and construction important link of the trommel screen ought to be reviewed. It should be able and sturdy to endure the needs of the application, such as the type of product being refined and the environmental conditions it will certainly undergo. The display dimension and arrangement are also critical factors to consider. The dimension of the holes or mesh in the display must be selected based upon the size of the product to be sorted. In addition, the screen arrangement, such as the number of sections and inclination angle, can influence address the effectiveness and performance of the trommel screen. Various other important considerations consist of the power resource, ease of upkeep, and any extra attributes or customization choices that may be needed for details applications. On the whole, by carefully considering these variables, one can pick a trommel screen that optimizes reusing output and fulfills the details needs of their procedure.

Methods to Maximize Reusing Output With Trommel Screens

To optimize reusing result with trommel screens, it is important to apply calculated methods that exploit on the display's capacities and maximize efficiency. One technique is to properly size the trommel screen based on the particular reusing application. Furthermore, it is vital to regularly maintain the trommel and examine display to make sure ideal performance.

Final Thought

Finally, trommel displays are crucial tools in making the most of recycling outcome. They successfully different and sort products, enabling for efficient processing and recovery of valuable resources. By taking into consideration key elements such as screen ability, upkeep, and size requirements, one can select the most suitable trommel display for their reusing operations. Executing strategies like proper material preparation and normal upkeep can better improve the performance and efficiency of trommel displays, inevitably causing a higher recycling result.

In recycling centers, trommel screens are commonly used to sort different types of recyclable materials, such as plastics, steels, and paper, making sure that each material is correctly classified and refined for additional usage.

Trommel screens are made with rotating round drums that have perforated plates or displays. The screen configuration, such as the number of areas and disposition angle, can impact the effectiveness and performance of the trommel display.To enhance recycling result with trommel displays, it is crucial to execute tactical strategies that take advantage of on the display's capacities and maximize efficiency. By considering crucial elements such as screen dimension, maintenance, and capacity needs, one can choose the most appropriate trommel screen for their recycling operations.